Our story

Our company, which is solely Hungarian owned, has been a major player in the machinery industry in Zalaegerszeg since 1994.

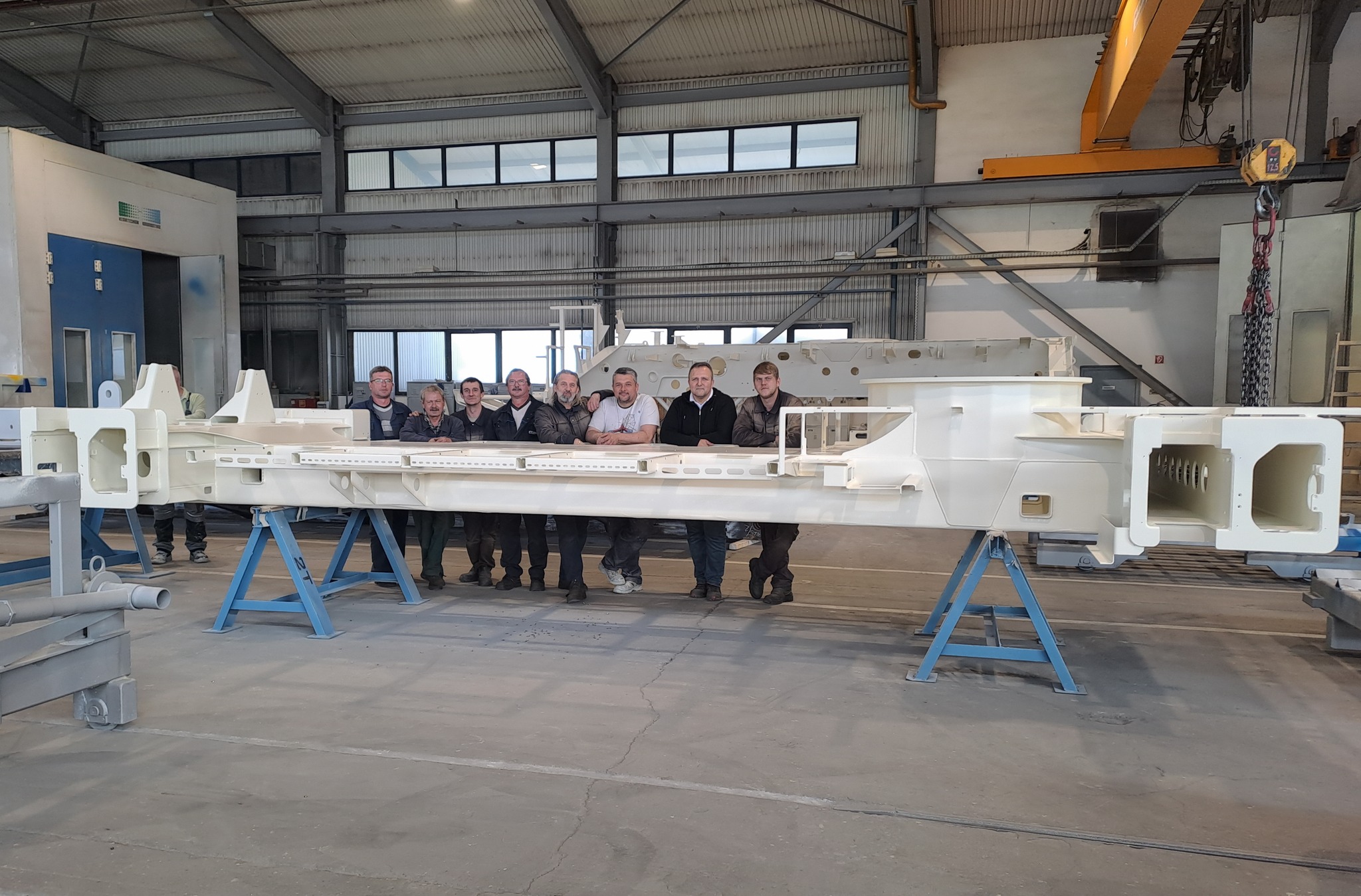

Our main field of activity is the production of lifting machines, cranes, steel structures, customized machines, components and parts of other construction machinery, mainly for export, as a supplier to renowned Austrian and German engineering companies. Among our most important products are welded structures made of high-strength fine-grained steel, such as mobile cranes and heavy-duty chassis. We have also been producing sub-assemblies, mainly maintenance crane components, as well as material handling equipment, roller conveyors and manipulators for our customers for many years.

THE HISTORY OF PYLON-94 ltd. FROM THE ESTABLISHMENT

1994

Pylon-94 Ltd. was founded.

1997

We produced the 100th piece of our company’s most defining product (mobile crane frame).

1998

The construction of our cutting workshop (1,300 m2) and assembly and painting workshop (1,600 m2) was completed.

With the expanded technological possibilities, we were able to produce entire assembled machines.

2005

Through technology transfer, the production of telescopic crane booms was introduced.

A special welding and straightening machine was installed.

A new 1,300 m2 hall was built for the production of crane booms.

2009

The GSI/SLV qualification was extended to the welding of S1300 QL quality steels.

This year also saw the commissioning of our welding robot and the opening of the company’s new office building.

2011

With the further expansion of our warehouse, cutting and preparation plant, our total production area reached almost 13,000 m2.

2016

100th heavy-duty chassis completed.

A new painting booth was put into operation.

2018

A new plasma cutting machine was installed.

2021

The 500th basket lift chassis and the 100th self-steering container chassis were completed.

2022

We built maintenance equipment for the Sydney Bridge in Australia.

This year, we were the first in the world to produce a heavy-duty truck chassis that could be split in two along its longitudinal axis.

2024

We produced the 200th piece of T460 chassis

(part of an aerial lift).